As part of our new security upgrades, you are requested to reset your password

Catalog

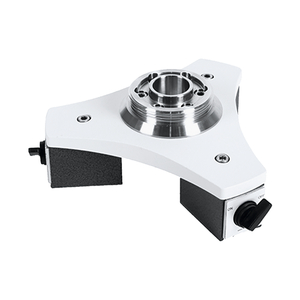

SKU: M00-694-270-000

Price:

$775.00

In Stock

SKU: M00-694-274-000

Price:

$775.00

In Stock

Added to your shopping cart.

Product availability by store location

Hours